Minimising downtime is critical to efficient and profitable manufacturing, it would be nice if nothing ever went wrong or stopped your production – but let’s face it that doesn’t happen in Manufacturing! When things do go wrong often the most time-consuming part of getting back up and running is troubleshooting the cause of the problem. This is why Nakamura Tome has developed an intelligent troubleshooting feature it is designed to help users quickly identify and resolve issues, ensuring maximum machine availability and productivity.

How Trouble Guidance Works:

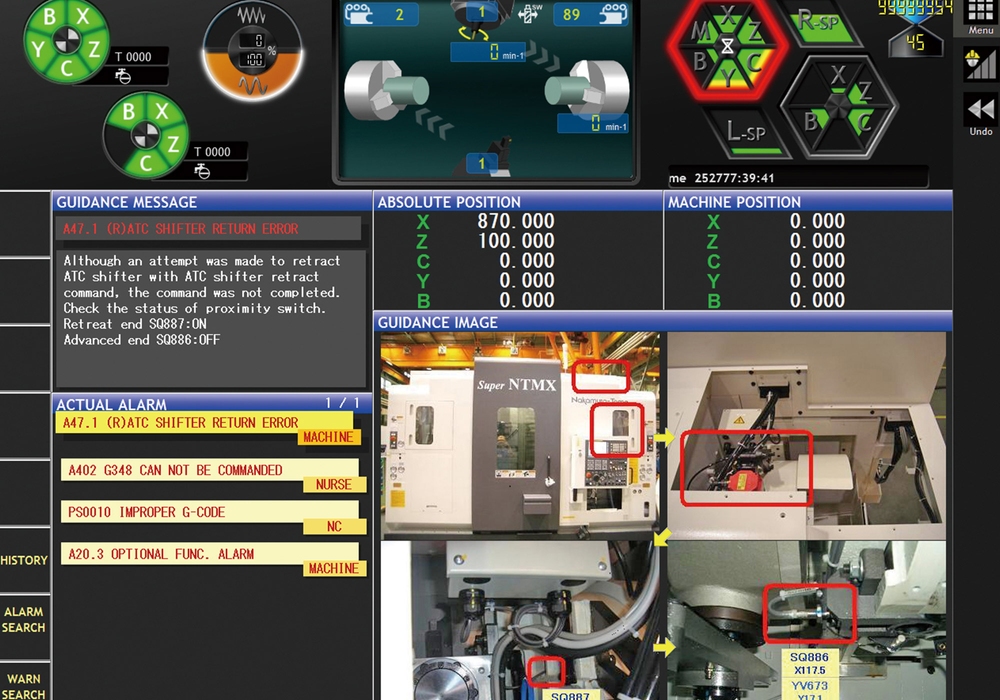

Trouble guidance window

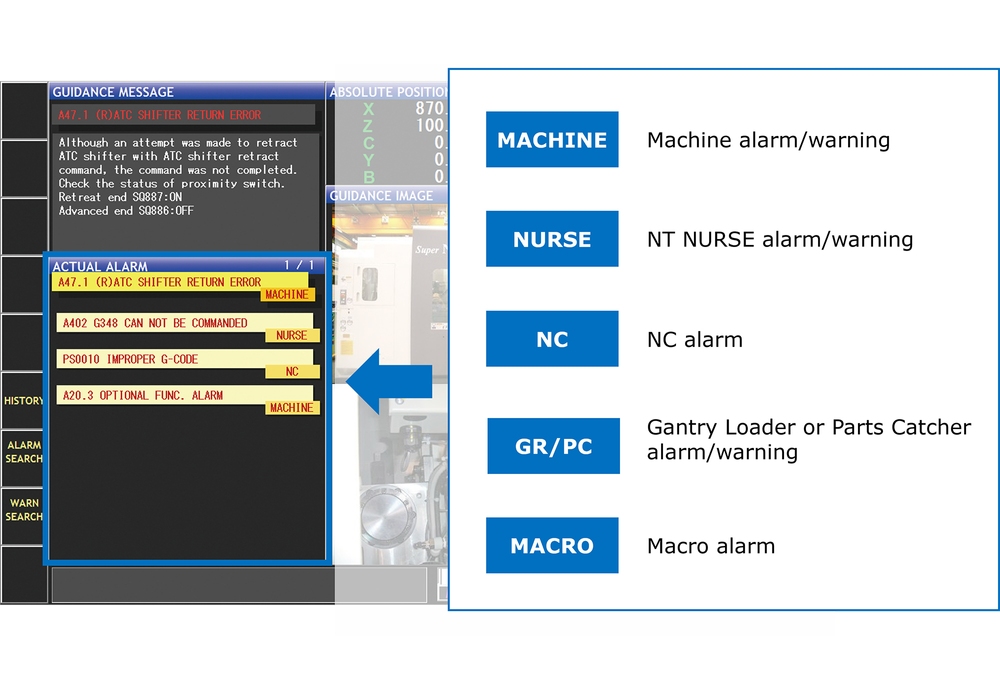

As you can see in the left picture below Trouble Guidance is a feature that shows users the cause of an alarm and guides them through quick troubleshooting. When an alarm is triggered, the Trouble Guidance window immediately pops up, providing users with detailed information about the alarm, its location, and step-by-step instructions for resolving the issue. The ACTUAL ALARM screen can display up to eight alarms simultaneously on one page, with a maximum of 24 alarm messages. These alarms are categorised into five distinct types (right hand picture below), making it easy for users to understand the root cause and take appropriate action.

Comprehensive alarm history

Users can also access the machine’s alarm and warning history by clicking the HISTORY icon. The system displays alarm history, warning history, and numerical control (NC) alarm history, with each screen showing the top 10 most frequently occurring alarms or warnings. This historical data empowers users to identify recurring issues and implement preventive measures, further reducing downtime and improving machine operations.

The Trouble Guidance function is available on a wide range of our machines, including the JX-200, JX-250, MX-100, NTRX-300/300L, NTY3-100, NTY3-150, NTY3-250, WY-100II, WY-100V, WY-150, WY-250L, WT-100, WT-150II, WT-250II, WT-300, NTJ-100, Super NTJ, and NEW TW-30.

For detailed information about the Trouble Guidance feature and its functionalities, please refer to sections 4-8, “Trouble Guide Screen,” in the Operation Manual for the NT-IPS SCREEN DISPLAY FUNCTION.

With the Nakamura-Tome Trouble Guidance feature, you can minimise machine downtime, maximise productivity, and enjoy the peace of mind that comes with efficient troubleshooting and maintenance support.

If you want to find out more about Nakamura-Tome Trouble Guidance contact one of our experts today.